In the bustling and highly regulated world of food production, ensuring the safety and quality of products is paramount. One critical component of this process is the use of food industry metal detectors. These devices play a vital role in safeguarding consumers from potential hazards and maintaining the integrity of food products.

The Importance of Metal Detectors in the Food Industry

Food safety is not just a regulatory requirement but a moral obligation for producers. Contaminants in food can lead to severe health issues, recalls, and damage to a brand’s reputation. Among various contaminants, metal particles are a significant concern due to their potential to cause physical harm. Metal detectors serve as a first line of defense against such contaminants.

- Consumer Safety: The primary reason for using food metal detectors is to protect consumers from ingesting metal fragments that could cause injury.

- Compliance and Regulations: Regulatory bodies such as the FDA and USDA have stringent guidelines regarding food safety. Metal detectors help ensure compliance with these regulations.

- Brand Protection: A single instance of contamination can tarnish a brand’s reputation. Metal detectors help maintain consumer trust by ensuring that the products are free from metal contaminants.

- Operational Efficiency: Detecting and removing metal contaminants early in the production process can prevent damage to equipment and reduce downtime.

How Metal Detectors Work

Metal detectors used in the food industry operate based on electromagnetic fields. When a product passes through the detector, it creates a magnetic field. If there is a metal contaminant present, it disrupts this field, triggering an alarm. Let’s break down the process:

- Detection Coil: The heart of the metal detector is the detection coil, which generates an electromagnetic field.

- Signal Processing: When a metal particle disrupts the electromagnetic field, the detector’s electronics process this change and determine if the disruption is significant enough to indicate contamination.

- Rejection Mechanism: Upon detection, the contaminated product is diverted from the production line, often through automated rejection systems like air blasts or pushers.

Types of Metal Detectors

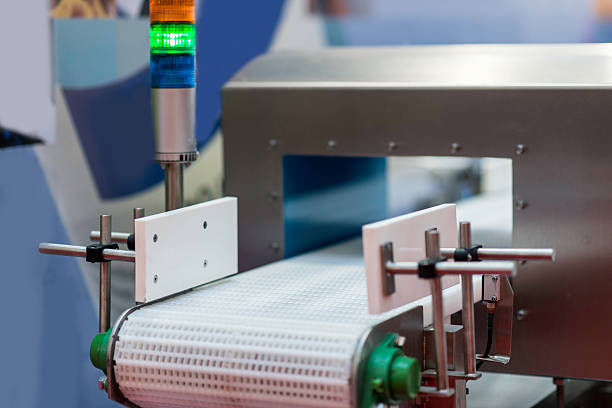

The food industry employs various types of metal detectors, each suited to different stages of production and types of products.

- Conveyor Belt Metal Detectors: These are commonly used in the final stages of production, where packaged goods pass through the detector. They are effective for products in bags, boxes, or other containers.

- Pipeline Metal Detectors: These are used for inspecting liquids, pastes, or slurries. They are installed directly into the production line’s piping system.

- Gravity Feed Metal Detectors: Ideal for dry, free-flowing products such as grains, powders, and spices. These detectors are installed at the point where the product falls through a gravity feed system.

- Compact Metal Detectors: These are used for smaller, individual items and are often integrated into other equipment such as check weighers.

Challenges and Solutions in Metal Detection

Despite their importance, metal detectors face several challenges in the food industry.

- Product Effect: Certain products, particularly those with high moisture or salt content, can mimic the presence of metal. This is known as the “product effect.” Advanced metal detectors use software algorithms to distinguish between actual metal contaminants and product effect.

- Environmental Factors: Temperature fluctuations, humidity, and vibration can affect the performance of metal detectors. Modern detectors are designed to be robust and resilient to these environmental factors.

- Metal Types and Sizes: Different metals (ferrous, non-ferrous, and stainless steel) have different detection sensitivities. Ensuring that the detector can identify all types of metals, regardless of their size, is crucial. Calibration and regular testing are essential to maintain detection accuracy.

Best Practices for Implementing Metal Detectors

To maximize the efficiency and reliability of metal detectors in the food industry, several best practices should be followed:

- Regular Testing and Calibration: Routine testing with certified test pieces ensures that the detector is functioning correctly. Calibration should be done according to the manufacturer’s guidelines and regulatory requirements.

- Staff Training: Operators should be adequately trained in the use and maintenance of metal detectors. They should understand how to perform tests, interpret results, and carry out basic troubleshooting.

- Documentation and Record Keeping: Keeping detailed records of tests, calibrations, and maintenance activities is essential for regulatory compliance and traceability.

- Integration with HACCP Plans: Metal detection should be an integral part of a Hazard Analysis Critical Control Point (HACCP) plan. Identifying critical control points and ensuring that metal detectors are correctly placed at these points can significantly reduce the risk of contamination.

The Future of Metal Detection in the Food Industry

The food industry continues to evolve, and so do the technologies used to ensure product safety. Innovations in metal detection are making the process more efficient, reliable, and integrated with other quality control systems.

- Advanced Algorithms: Future metal detectors will use more sophisticated algorithms to improve detection accuracy and reduce false positives caused by product effect.

- Internet of Things (IoT) Integration: Connecting metal detectors to a central monitoring system through IoT can provide real-time data and alerts, improving response times and decision-making.

- Automated Documentation: Automation in record-keeping and documentation will streamline compliance processes and reduce the risk of human error.

Also Read: Metal Detectors in Food Packaging: Ensuring Safety and Quality

Conclusion

Metal detectors are indispensable tools in the food industry’s quest to ensure safety and quality. By detecting and eliminating metal contaminants, these devices protect consumers, comply with regulations, and preserve brand integrity. As technology advances, metal detectors will become even more integral to the food production process, offering enhanced detection capabilities and greater integration with other quality assurance systems. For food producers, investing in the right metal detection technology and implementing best practices is not just a regulatory necessity but a commitment to delivering safe and high-quality products to consumers.