In the food industry, maintaining high standards of safety and quality is important. Regulatory compliance ensures that food products are safe for consumption and meet established standards. Food inspection systems play a crucial role in helping food manufacturers adhere to these regulations, preventing contamination, and ensuring that products are safe for consumers.

The Importance of Regulatory Compliance in the Food Industry

Regulatory compliance in the food industry is governed by various national and international bodies, including the Food and Drug Administration (FDA) in the United States, the European Food Safety Authority (EFSA) in the European Union, and other local health departments. These organizations establish guidelines and standards to ensure the safety, quality, and integrity of food products.

Non-compliance can lead to severe consequences, including product recalls, legal penalties, damage to brand reputation, and, most critically, harm to consumers. Therefore, maintaining regulatory compliance is not only a legal obligation but also a moral responsibility for food manufacturers.

The Role of Food Inspection Systems

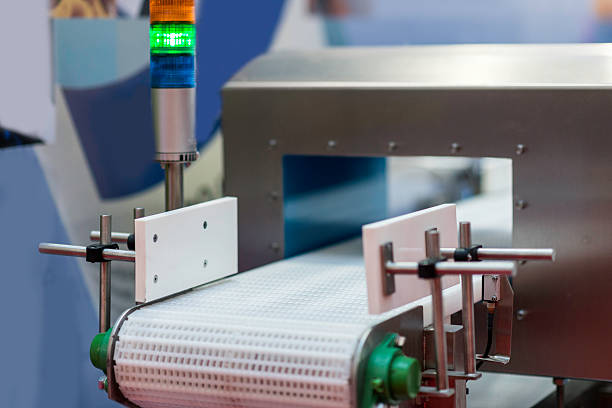

Food inspection systems are technological solutions designed to detect contaminants, ensure quality, and verify the integrity of food products. These systems are essential in meeting regulatory standards and include various types of equipment such as X-ray inspection systems, metal detectors, vision inspection systems, and checkweighers. Each system serves a unique purpose in the inspection process:

- X-ray Inspection Systems: These systems use X-ray technology to detect physical contaminants such as metal, glass, stones, and bone fragments. They are particularly effective for inspecting products with complex compositions, such as packaged goods, where visual inspection alone is insufficient.

- Metal Detectors: Food Metal detectors are used to identify metal contaminants in food products. They are highly sensitive and can detect both ferrous and non-ferrous metals, ensuring that metal fragments do not reach the consumer.

- Vision Inspection Systems: Vision systems use cameras and image processing software to inspect the appearance, shape, size, and color of food products. They ensure that products meet aesthetic and quality standards, such as proper labeling and packaging integrity.

- Checkweighers: Checkweighers verify that the weight of packaged food products is within specified tolerances. They ensure that products are neither underfilled nor overfilled, maintaining compliance with weight regulations and preventing economic losses.

How Food Inspection Systems Ensure Compliance

Food inspection systems contribute to regulatory compliance in several ways:

1. Detection of Contaminants

One of the primary functions of food inspection systems is to detect and eliminate contaminants. X-ray inspection systems and metal detectors identify foreign objects that could pose a health risk to consumers. By ensuring that no contaminants are present, these systems help manufacturers comply with regulations that mandate the absence of hazardous materials in food products.

2. Quality Control

Vision inspection systems play a crucial role in quality control by examining the visual aspects of food products. They ensure that products are free from defects, properly labeled, and packaged according to standards. This not only helps in maintaining product quality but also ensures compliance with labeling and packaging regulations.

3. Weight Verification

Checkweighers ensure that the weight of food products adheres to specified tolerances. This is important for compliance with regulations that govern product weight and volume. Accurate weight measurement prevents underfilling or overfilling, which could lead to regulatory penalties and consumer dissatisfaction.

4. Traceability and Record Keeping

Modern food inspection systems often come equipped with data logging capabilities. They record inspection results, providing traceability and documentation that can be used for regulatory audits. This data is crucial for demonstrating compliance with food safety standards and for identifying and addressing any issues that arise during production.

5. Continuous Improvement

Food inspection systems enable continuous monitoring and improvement of production processes. By identifying defects and contaminants early in the production line, manufacturers can take corrective actions promptly. This proactive approach helps in maintaining compliance and improving overall product quality.

Technologies Involved in Food Inspection Systems

Advancements in technology have significantly enhanced the capabilities of food inspection systems. Some of the key technologies involved include:

1. X-ray Imaging

X-ray imaging technology allows for the detection of contaminants that are not visible to the naked eye. It can penetrate various materials, making it ideal for inspecting packaged goods. Modern X-ray systems use high-resolution imaging and advanced algorithms to identify even the smallest foreign objects.

2. Electromagnetic Induction

Metal detectors use electromagnetic induction to detect metal contaminants. When a metal object passes through the detector’s magnetic field, it creates a disturbance that triggers an alarm. This technology is highly sensitive and can detect metals of different sizes and compositions.

3. Machine Vision

Machine vision systems use cameras and image processing software to inspect food products. They can identify defects, verify labels, and ensure packaging integrity. Machine vision technology is constantly evolving, with improvements in resolution, processing speed, and artificial intelligence (AI) algorithms.

4. Load Cells

Checkweighers use load cells to measure the weight of food products accurately. Load cells are sensors that convert force (weight) into an electrical signal. They provide precise weight measurements, ensuring that products meet regulatory requirements.

Benefits of Food Inspection Systems

Implementing food inspection systems offers numerous benefits to food manufacturers:

1. Enhanced Food Safety

By detecting contaminants and ensuring quality, food inspection systems significantly enhance food safety. This reduces the risk of foodborne illnesses and protects consumers from harm.

2. Regulatory Compliance

Food inspection systems help manufacturers comply with stringent regulatory standards. This minimizes the risk of legal penalties, product recalls, and damage to brand reputation.

3. Improved Product Quality

Inspection systems ensure that only high-quality products reach the market. This leads to increased customer satisfaction and loyalty, as consumers can trust the safety and quality of the products they purchase.

4. Operational Efficiency

Automated inspection systems streamline the production process, reducing the need for manual inspection and minimizing errors. This increases operational efficiency and reduces costs associated with rework and product recalls.

5. Data-Driven Decision Making

The data collected by food inspection systems can be analyzed to identify trends and areas for improvement. This enables manufacturers to make informed decisions, optimize processes, and enhance overall product quality.

Also read about the Significance of a Food Safety Inspection System.

Conclusion

Regulatory compliance is a critical aspect of the food industry, ensuring that products are safe for consumption and meet established standards. Food inspection systems play a vital role in helping manufacturers achieve compliance by detecting contaminants, ensuring quality, and providing traceability. The technologies involved in these systems, including X-ray imaging, electromagnetic induction, machine vision, and load cells, have revolutionized the inspection process. By implementing food inspection systems, manufacturers can enhance food safety, improve product quality, and maintain regulatory compliance, ultimately protecting consumers and their brand reputation.