Accurate weight measurement is essential for businesses across various industries, from manufacturing and warehousing to logistics and retail. Choosing the right type of scale can significantly impact operational efficiency, safety, and cost management. Two popular options for industrial weighing are pallet scales and floor scales. While both serve the purpose of weighing heavy loads, their designs, features, and applications vary significantly. Understanding these differences will help you determine which scale fits your business needs best.

Understanding Pallet Scales

What Are Pallet Scales?

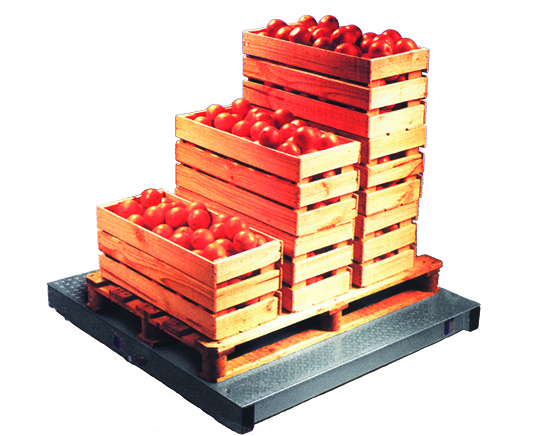

Pallet scales are specialized weighing devices designed to measure the weight of palletized goods. They typically feature a low-profile design that accommodates pallets and are often equipped with a U-shaped frame or built into pallet jacks. Pallet scales are portable, making them ideal for dynamic work environments where goods are frequently moved.

Key Features of Pallet Scales

- Portability: Many pallet scales come with wheels or are integrated into pallet jacks, allowing for easy mobility.

- Low Profile: Their design enables effortless loading and unloading of pallets.

- Quick Setup: Pallet scales are easy to set up and can be used in various locations within a facility.

- Versatility: They can weigh different types of pallets, crates, and containers.

Advantages of Pallet Scales

- Enhanced Mobility: Pallet scales can be moved to different locations, making them ideal for businesses with multiple weighing stations or dynamic workflows.

- Time Efficiency: The ability to weigh goods directly on the pallet eliminates the need for additional handling, saving time and reducing labor.

- Space Saving: Their compact and portable design is perfect for facilities with limited space.

Limitations of Pallet Scales

- Weight Capacity: Pallet scales typically have a lower weight capacity compared to floor scales, which might limit their use for extremely heavy loads.

- Stability: They may not be as stable as fixed floor scales, especially when weighing unevenly distributed loads.

Understanding Floor Scales

What Are Floor Scales?

Floor scales are robust, stationary weighing platforms designed to handle large, heavy items. These scales are installed directly on the ground and are commonly used in warehouses, factories, and shipping centers. Their sturdy construction ensures accurate and stable measurements, even for oversized loads.

Key Features of Floor Scales

- High Capacity: Floor scales can handle extremely heavy loads, often exceeding several tons.

- Durability: Built with rugged materials, these scales are designed for long-term use in demanding industrial environments.

- Large Platform: Their spacious platforms can accommodate a wide range of items, from pallets to machinery.

- Fixed Installation: Floor scales are typically installed in a fixed location, ensuring stability and reliability.

Advantages of Floor Scales

- High Weight Capacity: Floor scales are ideal for weighing heavy and bulky items, making them suitable for industries that deal with substantial loads.

- Stability and Accuracy: The fixed installation ensures stable and accurate measurements, even for unevenly distributed weights.

- Versatility: With their large platforms, floor scales can weigh a variety of items, including pallets, equipment, and raw materials.

Limitations of Floor Scales

- Immobility: Unlike pallet scales, floor scales are not portable and are limited to a fixed location.

- Space Requirement: Their larger size and fixed installation require sufficient floor space.

- Initial Cost: The cost of purchasing and installing floor scales may be higher compared to pallet scales.

Factors to Consider When Choosing Between Pallet Scales and Floor Scales

Selecting the right scale for your business involves evaluating your operational needs, budget, and space constraints. Here are key factors to consider:

1. Nature of Operations

- If your business involves frequent movement of goods and requires flexibility, pallet scales are an excellent choice.

- For operations that require weighing large or heavy items in a fixed location, floor scales are more suitable.

2. Weight Capacity Requirements

- Determine the maximum weight you need to measure regularly. If your loads exceed the capacity of pallet scales, floor scales are the better option.

3. Space Availability

- Businesses with limited space may benefit from the compact design of pallet scales.

- If space is not a constraint, floor scales provide greater versatility and capacity.

4. Budget Constraints

- Pallet scales are generally more affordable and require minimal installation costs.

- Floor scales, while more expensive, offer higher durability and capacity, making them a long-term investment.

5. Frequency of Use

- For high-frequency weighing tasks, floor scales provide durability and consistent performance.

- Pallet scales are ideal for occasional or moderate use, especially when mobility is essential.

Applications in Different Industries

Pallet Scales

- Warehousing and Distribution: For weighing goods during loading and unloading processes.

- Retail: Ideal for inventory management in large retail stores.

- Agriculture: Used for weighing crates of produce, feed, or other agricultural products.

Floor Scales

- Manufacturing: Suitable for weighing raw materials, components, and finished products.

- Logistics: Used in shipping centers for accurate weight measurements of packages and freight.

- Construction: Ideal for weighing heavy machinery and construction materials.

Combining Both Scales

In some cases, businesses may benefit from using both pallet scales and floor scales. For instance, a warehouse might use pallet scales for quick, on-the-go measurements and floor scales for weighing heavier loads in a central location. This combination provides flexibility and ensures all weighing requirements are met efficiently.

Also Read: Unlocking Efficiency: The Role of Platform Scales in Industrial Operations

Maintenance and Calibration

Regardless of the type of scale you choose, regular maintenance and calibration are crucial for ensuring accuracy and longevity. Pallet scales, due to their mobility, may require more frequent calibration, while floor scales benefit from their stationary setup. Partnering with a reliable service provider can help maintain the performance of your scales.

Conclusion

Choosing between pallet scales and floor scales depends on your specific business needs, including the nature of your operations, weight capacity requirements, and space constraints. Pallet scales offer portability and convenience, making them ideal for dynamic environments, while floor scales provide stability and high capacity for demanding industrial tasks. By carefully assessing your requirements, you can invest in the right weighing solution to enhance efficiency, accuracy, and productivity in your business.